Product Description

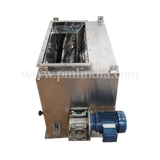

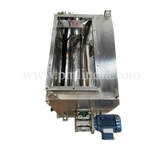

- Magnetic Drum Separators are of self-cleaning type and provide continuous removal of ferrous contamination from a wide range of free-flowing bulk and granular materials in high-volume applications.

- Drums can be ordered with or without housing.

- Magnetic Drum Separator system is a complete machine with Stainless Steel 304 / 316

Housing & Drive system. Only the drum separator unit can also be supplied. - The Drum Separators are available in two types:

High Intensity – (Ndfeb Magnet – 4500 gauss), for Operating Temperature of 80˚C(Max.)

Low Intensity - (Ferrite Magnet - 1200 gauss), for Operating Temperature of 250˚C(Max.) - Ferrous fine particles, nuts, bolts, pins, nails and other tramp metal from free-flowing granular material can be arrested effectively.

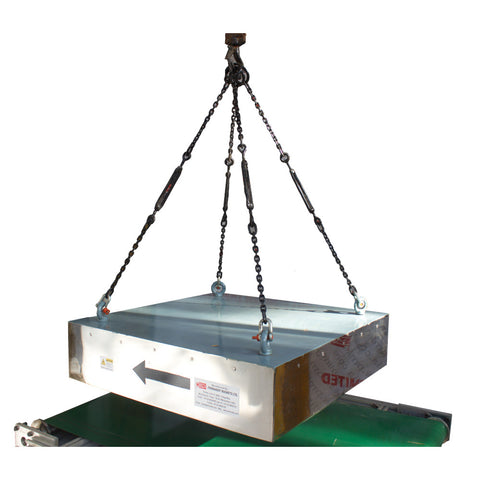

PML IFR Machine at TATA Tea Ltd, Munnar plant

How to use Magnetic Drums?

When material flows onto the drum, a stationary magnetic assembly inside the unit's shell captures tramp metal and holds it securely to the drum's stainless steel surface. With contaminants removed, the good product falls freely to a discharge point. As the drum rotates, cleats sweep the ferrous debris through and out of the magnetic field. The tramp metal is discharged separately, creating continuous self-cleaning separation. PML is drum separator manufacturer in india.

Features:

Magnetic Drums have the following features:

- Designed for continuous separation and self-cleaning. Ideal for high-flow, heavy-contamination applications. It comes with Stainless steel drum and mild steel or stainless steel housings

- Maximum Recovery of Ferrous Metals

- Minimum Maintenance

- They require minimum space and are simple to operate.

- They are flexible enough to be applied for various purposes

Advantages:

- Helps in removing ferrous particles from any nonferrous powder and granules

- Ideal for plastic, food, fertilizer, pharmaceutical, chemical, glass, and continuous process plants

- Provide utmost protection to crushers, grinders, pulverizes, and allied equipment

- Can be used for mining and ore dressing industry

- Eliminate fire hazards and explosions in plants dealing with explosive material.

- Save money, time and labor by reducing break-down time and improving quality.

- The machine can be equipped with PLC & VFD.

Construction:

The magnetic drum separator consists of a rotating drum and stationary drum magnet designed as per the specific needs of the customer. The Drum separator is supplied with the drive system and SS 304/316 housing along with a feed regulating valve.

Standard Magnetic Drum Separators with SS Housing and Drive arrangement:

| Low-Intensity Magnetic Drum Separator (1200 Gauss) suitable for Max. Temperature 250˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDHL1 | Ferrite | 250 | 300 | 300 | 1,200 |

| MDHL2 | Ferrite | 250 | 300 | 450 | 1,200 |

| MDHL3 | Ferrite | 250 | 400 | 600 | 1,200 |

| MDHL4 | Ferrite | 250 | 450 | 750 | 1,200 |

| MDHL5 | Ferrite | 250 | 500 | 1000 |

1,200 |

| High-Intensity Magnetic Drum Separator (4500 Gauss) suitable for Max. Temperature 80˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDHH1 | NdFeB | 80 | 300 | 300 | 4,500 |

| MDHH2 | NdFeB | 80 | 300 | 450 | 4,500 |

| MDHH3 | NdFeB | 80 | 400 | 600 | 4,500 |

| MDHH4 | NdFeB | 80 | 450 | 750 | 4,500 |

| MDHH5 | NdFeB | 80 | 500 | 1000 | 4,500 |

Standard Magnetic Drum without Housing and Drive( Only Drum Separator ):

| Low-Intensity Magnetic Drum Separator (1200 Gauss) suitable for Max. Temperature 250˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDL-1 | Ferrite | 250 | 300 | 300 | 1,200 |

| MDL-2 | Ferrite | 250 | 300 | 450 | 1,200 |

| MDL-3 | Ferrite | 250 | 400 | 600 | 1,200 |

| MDL-4 | Ferrite | 250 | 450 | 750 | 1,200 |

| MDL-5 | Ferrite | 250 | 500 | 1000 |

1,200 |

| High-Intensity Magnetic Drum Separator (4500 Gauss) suitable for Max. Temperature 80˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDH-1 | NdFeB | 80 | 300 | 300 | 4,500 |

| MDH-2 | NdFeB | 80 | 300 | 450 | 4,500 |

| MDH-3 | NdFeB | 80 | 400 | 600 | 4,500 |

| MDH-4 | NdFeB | 80 | 450 | 750 | 4,500 |

| MDH-5 | NdFeB | 80 | 500 | 1000 | 4,500 |

PML also makes custom-designed Magnetic Drum Separators to precisely fit customer’s applications.

The following information is required:

- Type of material from which Iron is to be separated. (Sticky, Granular, Free-flowing, Lumps, etc)

- Size and level/percentage of contamination

- The flow rate of material

- Size/Density of the material particle

Applications:

The Magnetic Drum filters out iron contamination and hence is widely used in all the processing industry for the separation of iron contamination from:

- Minerals and Chemicals

- Food and Flour

- Plastics

- Grains

- Sand

- Fertilizers

- Abrasives

- Glass

- Slag

- Ores

- Rock

- Refractory

Why PML Magnetic Drum Separator?

- 45 years of experience in the design and development of Permanent Magnets and Magnetic Systems.

- Magnet Drum Separators are available in a wide range from 1200 Gauss (up to 250°C) to high intensity 4500 Gauss (up to 80°C).

- Customized Design.

- PML offers comprehensive systems using 2/3 drum separators with other magnetic systems in series to ensure output contamination level to minimum PPM.

- Services such as magnetic calibration/Audit are available.

Some of PML’s Valued customers:

- Ambuja Cements Ltd

- J.K. White Cements Ltd

- Ultratech Cements Ltd

- Sterlite Industries Ltd

- Goa Carbon Ltd

- Trivent Earth Movers Pvt Ltd

- Chettinad Cements Ltd

- Shi Vishnu Cements Ltd

- Gujrat Sidhi Cements Ltd

- Metso Minerals Pvt Ltd

- Kerala Chemicals & Proteins Ltd, Kochi

- Gujrat Fluorochemical Ltd Bharuch

- Praweg Conveyors Thane

- AGI Glasspac Hyderabad

FAQ for Magnetic Drum Separator

- 1) How much maximum magnetic power can be get?

- Ans - 4500 Gauss. Which is sufficeint to remove the fine size iron contamination.

- 2) How to clean iron particles from drum?

- Ans - Drum seoarator is a self cleaning system. It separates iron & non iron material through two different outlets.

- 3) Where to install it?

- Ans - Below material feeding system like screw conveyor, bucket elivator, conveyor belt, vibro feeder etc.

- 4) Does it require power supply?

- Ans - Yes, Magnetic drum rotates with the help of the induction motor. PLC & VFD can configured witht the system.

- 5) What is the drum rpm rate?

- Ans - 20 rpm.

- 6) Can we feed material manually?

- Ans - Yes but it is always recommended to use feeding system for regulated & even material feeding. This will help for better iron removal from material.

- 7) How should i select the magnet size?

- Ans - Please select PML standard model as per material flow rate & type of iron contamination.

- 8) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 9) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 10) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 11) What is the M.O.C for the Housing, Hopper & Structure.

- Ans - M.O.C for the drum, housing, hopper is stainless steel only, Structure of the drum separator is made up of MS.

- 12) Is this magnetic drum separator efficient to remove 100% iron contamination from the material?

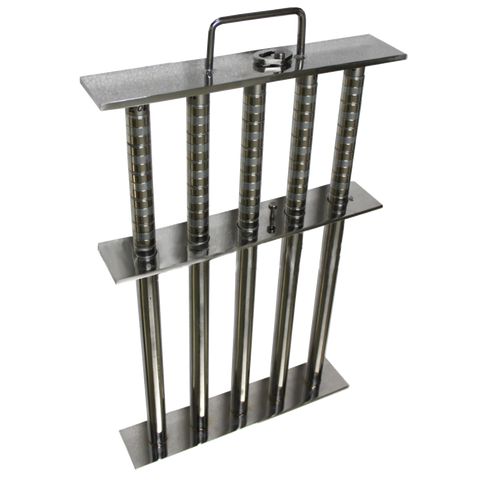

- Ans - It is advisable to use 2 stage drum separator, so that material can be double passed for more separation. OR Customer can install Magnetic grill of 11000 gauss at outlet of the system.

Our Valuable Customers for Magnetic Drum Separator

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|