Product Description:

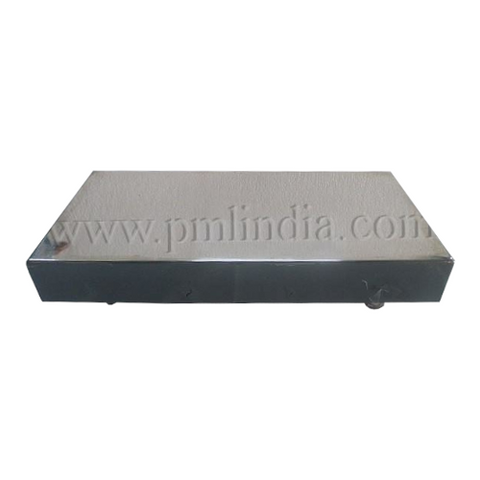

Magnetic Plates are important industrial iron separators that are used for the separation of fine ferrous materials and tramp iron from many types of free-flowing and pneumatically conveyed material like corn, sugar, flour, gravel, plastic, and others granular materials.

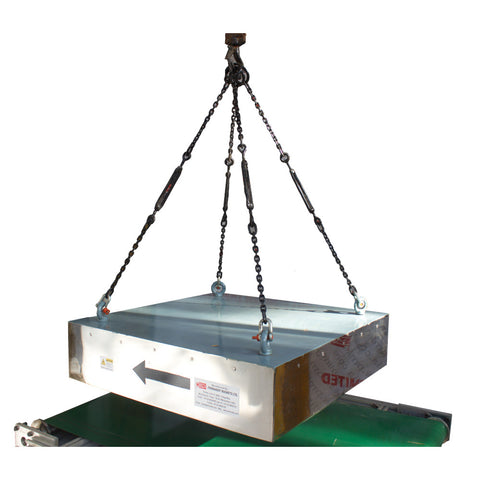

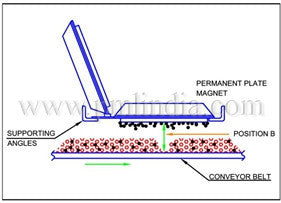

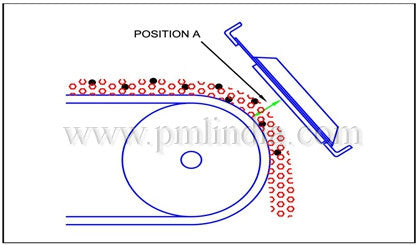

The Plate Magnets also go very well with powdery, moist, lumpy, and abrasive products and large debris that might choke, bridge, or cause rapid wear in cartridge-based separators. Plate magnets are flexible enough to be deployed above conveyors or below conveyor drive pulleys to capture contaminants. They are available in both flat and curved shapes and can be installed either above or at the discharge end of material flow.

Application:

Magnetic plates are extensively used in CTC Tea machinery and in Biscuit stacking machines. They are also used for separating trapped iron in industries such as:

- Food (Tea, Spices, Coffee, Cocoa, Milk Powder, etc.)

- Tobacco

- Chemicals

- Fertilizers

- Pharmaceuticals

- Foundry Sand

- Cattle Feed Materials

- Minerals

- Detergents

- Conveying of lightweight tin containers

- Conveying of M.S. sheets using multiple plates

How Does it Work?

Lighter Strength Plate Magnets offer cost-effective choices for applications with lower product flow rates, lower conveyor speeds, or thinner burden depths. High Strength Magnetic Plates with Strontium Ferrite Magnets / Rare Earth magnets can attract metal particles from thin layers of product conveyed on flat belts from a distance of 6”.

- Attract ferrous tramp from flat-belt.

- Powerful Ceramic magnet reaches deep into conveyed material up to 6”.

Threaded holes are provided for easy mounting of these plates with other convenient options.

For Iron Removal, Magnetic Plates are generally located above the material flow attracting the iron particles. The Magnetic Separation Process involves the magnetic field penetrating the product flow and grabbing tramp iron as it passes by the Plate. The concentrated field holds tramp iron tightly to the magnet surface until removed during the cleaning process. For the Separating of Ferromagnetic material like Tin/M.S. sheets and containers from conveyor belts, multiple Magnetic Plates at various locations are used. This prevents the falling off of sheets/containers back into the conveyor.

Features

- Efficient cost-saving recovery of harmful tramp iron in free-flowing materials

- Plate magnets can be mounted both, above and below the product flow

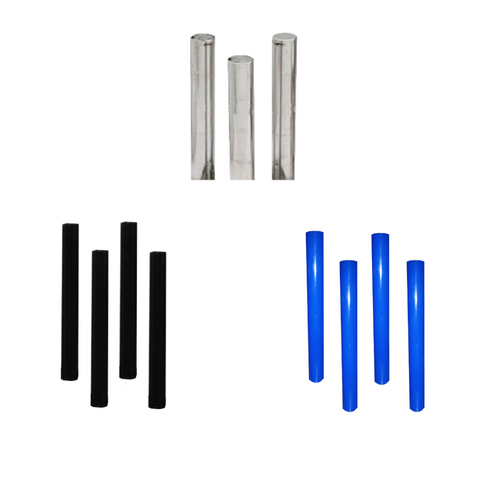

- Magnets like ceramic or rare earth magnets are normally used in plate

- Magnetic separators capture maximum common ferrous debris

- Durable stainless steel construction

- For easy cleaning, hanging plates can be swung out

- The Plate Magnets can be cleaned manually also

- Simple to install and have no maintenance

- Lightweight and user-friendly

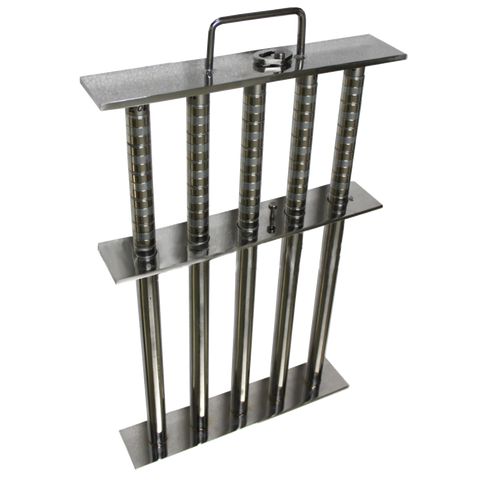

There are two Types of Plate Magnets:

- High Strength Magnetic Plates - (NdFeb Magnet – 4500 Gauss)

| HIGH-INTENSITY MAGNETIC PLATE - 4500 ± 500 GAUSS | ||||

|---|---|---|---|---|

| OPERATING TEMP - 80˚C | ||||

| Model Name | Model No. | SIZE (A x B x C) | WEIGHT (KG/APPROX) | ATTRACTION DISTANCE |

| MAGNETIC PLATE | HMP - 10 | 100 x 100 x 31 HT | 2 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 15 | 150 x 150 x 31 HT | 4 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 20 | 200 x 200 x 31 HT | 7.5 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 25 | 250 x 250 x 31 HT | 12 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 30 | 300 x 300 x 31 HT | 16 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 35 | 350 x 350 x 36 HT | 26 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 40 | 400 x 400 x 36 HT | 35 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 45 | 450 x 450 x 36 HT | 41 | 3" TO 4" |

| MAGNETIC PLATE | HMP - 50 | 500 x 500 x 36 HT | 50 | 3" TO 4" |

- Low Strength Magnetic Plates - (Ferrite Magnet – 1200 Gauss)

| LOW-INTENSITY MAGNETIC PLATE - 1200 ± 300 GAUSS | ||||

|---|---|---|---|---|

| OPERATING TEMP - 250˚C | ||||

| Model Name | Model No. | SIZE (A x B x C) | WEIGHT (KG/APPROX) | ATTRACTION DISTANCE |

| MAGNETIC PLATE | LMP - 10 | 100 x 100 x 46 HT | 3 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 15 | 150 x 150 x 46 HT | 5 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 20 | 200 x 200 x 46 HT | 9 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 25 | 250 x 250 x 46 HT | 13 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 30 | 300 x 300 x 46 HT | 19 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 35 | 350 x 350 x 51 HT | 29 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 40 | 400 x 400 x 51 HT | 38 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 45 | 450 x 450 x 51 HT | 46 | 4" TO 5" |

| MAGNETIC PLATE | LMP - 50 | 500 x 500 x 51 HT | 58 | 4" TO 5" |

Construction

Magnetic Plates are available in a flat and curved shape with required dimensions.The magnetic plates are made of either Ferrite or NdFeb magnets depending upon the required flux intensity. The magnetic surface is of Stainless Steel 304/316.

Specification

- The compact design of these powerful magnetic separators makes them simple

- Standard installations involve hinged models for swing–open cleaning

- Plate Type Suspended Magnets are also available without hinges for stationary or suspended installations

- Rare Earth is standard for food and pharmaceutical applications where product purity is paramount

Information Required for Design of Magnetic Plates

- Type of material

- Flow rate

- Size and concentration of contamination

- Flow passage dimensions

Why PML Magnetic Plate?

- PML has been a Permanent Magnet Manufacturer for over 45 years and has great experience in the design and development of Permanent Magnets and Magnetic Equipment

- Magnet plates are available in a wide range from 1200 Gauss to high intensity 4500 Gauss

- Customized Design

- Services such as Magnetic calibration/Audit are available

- PML's Magnetic Equipment is known to provide excellent Magnetic Separation of Material

FAQ for Magnetic Plate

- 1) From how much distance it can attract iron ?

- Ans - Attraction distance is depends on the size of magnetic plate. The standard range varies from 2 to 6 Inch.

- 2) How to remove catched iron from magnetic plate?

- Ans - The catched iron particles are need to be removed manually. Wear hand gloves to avoid injury

- 3) Is there any on / off switch provided to magnet?

- Ans - No. It is permanent magnet which is always in on condition.

- 4) What are the installation arrangement provided with the plate?

- Ans - The eye bolts & hinges can be provided to hang the plate Or Tapping holes to place it on table / stand.

- 5) Can we cut the magnetic plate?

- Ans - No. Magnetic Plate is made up of magnets, M.S.Plate. Cutting can damage the magnetic circuit.

- 6) Is the plate both side have magnetism?

- Ans - No only one side of plate is magnetic. Another side is of M.S. & is used for installation.

- 7) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 8) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 9) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 10) Can we use magnetic plate over conveyor belt?

- Ans - Yes. Magnetic Plate should be used on conveyor belt having maximum speed of 1meter/second. Attraction distance will be 2" to 4".