Concept and Application

Motors play a crucial role in virtually every human process and action, powering a vast array of equipment, devices, and systems. With the growing demand for machinery, devices, and electric vehicles, the number of motors being used has been steadily increasing. This trend has had a particularly notable impact on the BLDC (brushless DC) motor market in India. BLDC motors are increasingly in demand due to their efficiency, durability, and versatility, particularly in the context of the expanding railways, metros, and bullet trains. Additionally, rapid urbanization has spurred a greater need for elevators and escalators, which also rely on BLDC motors. Furthermore, BLDC motors are now widely used in everyday applications such as fans, air conditioners, and automobiles.

PML Scope:

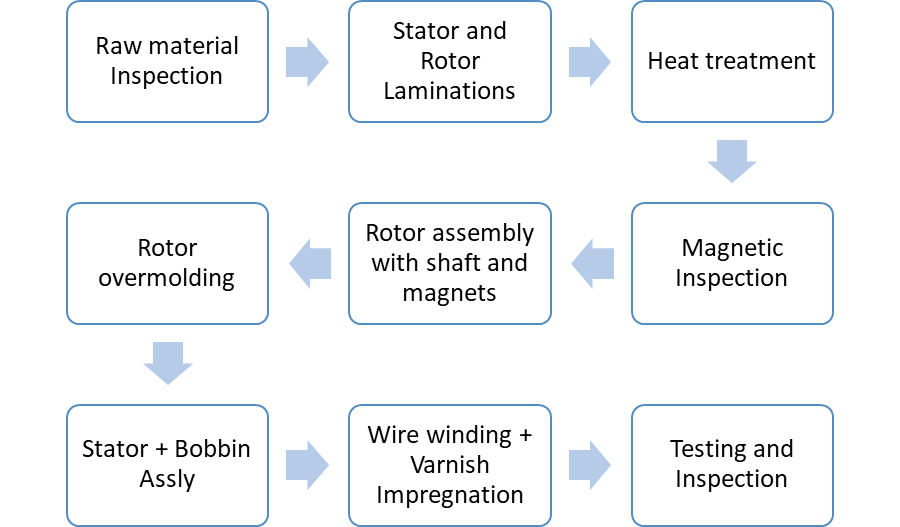

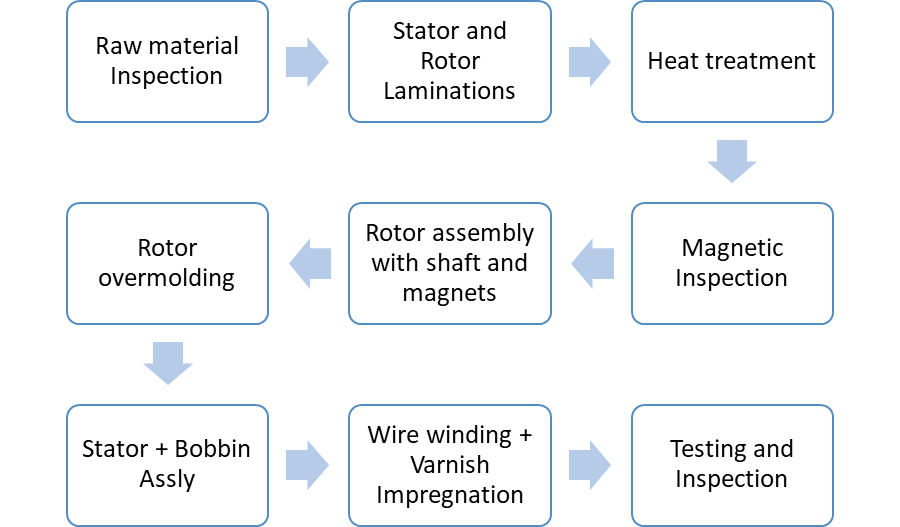

Process flow for manufacturing of Rotor and stator assemblies for BLDC Motors

- We utilize a state-of-the-art hydrogen annealing process to enhance the permeability of the materials used in our motors while reducing core losses. This results in an overall improvement in motor performance.

- Our heat treatment and subsequent oxidation process are designed to reduce stamping stress and increase inter-laminar resistance. These measures help to improve the overall durability and reliability of our motor components

Annealing service with temperature mapping

D. Magnetic / Mechanical simulation, Magnetic Inspection

2D Simulation of Stator and rotor

3D Simulation of Stator and rotor

Magnetic checking

3D-Simulation

E. Molding and Over molding facility

- Ferromatic / Dr. Boy : 25 ton to 110 Tons : For precision Bobbin Molds

- Vertical injection Molding: 25 ton & 85 Ton: Specifically designed for Insert Molding of Rotors

F. Automatic wire harness and sophisticated core and needle winding facility

Wire cutting/ stripping/twisting/crimping

Needle winding machine

Core winding machines

Needle winding machine

G. Varnish Impregnation : Automatic trickle varnish machine

H. Testing facility

Product testing at 20Khz

Testing mA, mV, L, AI, DC+AC test

VMM

Magnetic surface gauss(G) tester

CMM

Stack strength tester

I. Capabilities

PML can help in design optimization and manufacturing of Stator and Rotor assemblies for

- Application : Stator and Rotor, Micro motors, BLDC motors

- Industry : Conventional, Hybrid, Electric Vehicles, Medical devices

- Material Properties: Refer this link to view material properties of nife-soft-magnetic-alloys: Click Here

| Name |

Size range in MM |

No. of Poles |

Winding Class |

Phase |

Frequency |

Mounting |

| Stator & Rotor |

O.D. |

I.D. |

Height |

4 to 20 |

H |

1 and 3 |

50 Hz |

O.D. |

| 40 - 120 |

20-80 |

15-50 |

J. Advantages

PML can help in design optimization and manufacturing of Stator and Rotor assemblies for

- Strong expertise on knowing materials, magnets and magnetic system makes ease for new development.

- Offers designing and prototyping services.

- Designing and process optimization to reduce eddy current.

- Flexible capacity to accommodate low as well as higher volumes

- Knowing and delivering the required quality.

- One stop solution: All major facilities are under one roof.

FAQ for Rotor and Stator Assembllies

Q.1. What is role of stator and rotor in BLDC motor?

- Brushless DC Motors utilize a stator with an armature (coil winding) and a rotor made of permanent magnets.

When a direct current (DC) is applied to the stator's armature, it generates a magnetic field.

However, if a fixed DC current is used, the rotor cannot turn.

Therefore, it is necessary to continuously switch the phases of the stator windings using an electronic control circuit.

The rotor's magnet tries to align with the energized winding pole (electromagnet) of the stator.

As soon as the rotor magnet aligns, the next pole of the stator is energized, which keeps the rotor in an aligned (running) condition.

Q.2. What is the advantage of BLDC motors over Brushed DC Motors ?

-

Brushes in DC motors wear out and require replacement, limit the number of poles, and can create sparks.

Brushless DC motors eliminate the need for brushes, resulting in improved reliability and reduced maintenance requirements.

Q.3. What are benifits of BLDC over Brushed DC Motors?

- More Reliability. Increased efficiency & performance with respect to weight. No / Less down time for maintenance. No Sparks / Noise.