Iron Filing Removal Machine

Available

IFR Introduction

Iron is one of the most abundant materials in nature and is extensively used across various industries due to its superior mechanical properties and availability compared to other materials. Most products are manufactured on machinery and equipment that incorporate iron, which leads to iron contamination in the products.

Iron contamination can occur in different forms—loose, compound, or alloy—depending on the process. While it is an inherent part of production, iron contamination is undesirable in most products, with permissible levels governed by BIS and other international standards, particularly in the food processing industry.

Iron Removal System

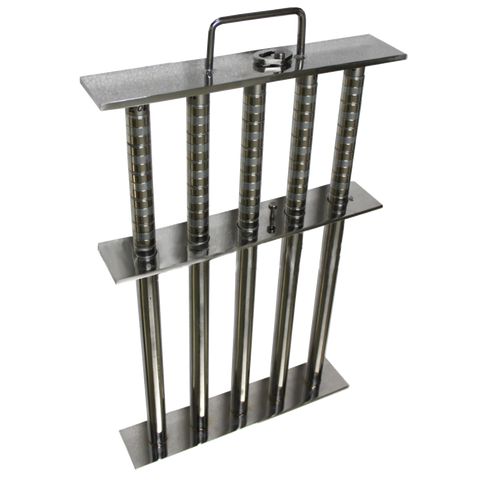

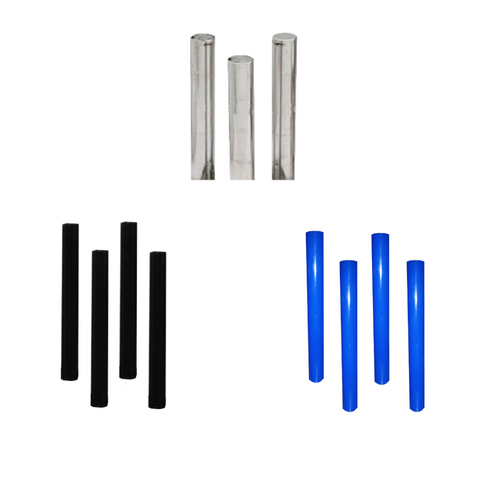

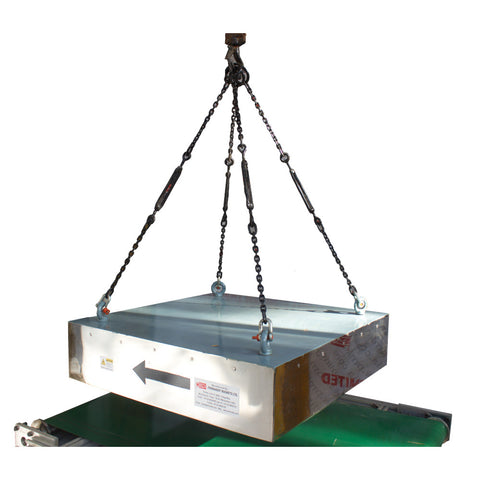

One of the most common methods to mechanically separate iron is through magnetic equipment. All food processing units rely on these systems, which can use either permanent magnets or electromagnets. Several types of magnetic devices, such as magnetic drums, pulleys, grills, plates, and over-band magnets, are employed for iron separation.

While these devices are used by various industries, they are often deployed in isolation. Until recently, no comprehensive system combined the strengths of these various devices into an efficient iron separation solution.

Application in Tea Processing

This iron removal machine is designed specifically to remove iron from tea. The system is installed between the tea storage areas and the blending station and is capable of processing up to 4,500 kg of tea per hour. The machine ensures that the processed tea contains no more than 30 ppm of pure iron or 400 ppm of iron mixed with tea.

However, it should be noted that the output quality depends on factors like the input quality, flow rate, iron contamination size, and the magnetic systems used. Therefore, it is recommended to calculate a cleaning ratio to measure the system's efficiency.

System Specifications

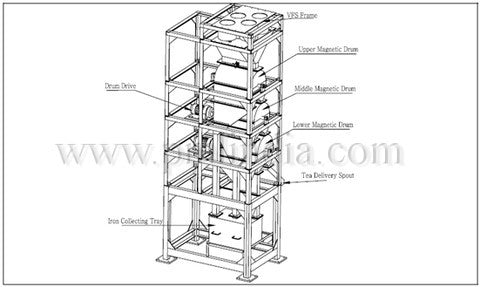

The machine occupies approximately 15 square meters of floor space and is 5.5 meters in height. It comprises several components including an input bin, vacuum feeding system, magnetic drum separators, a geared motor drive, and a control panel.

Tea is fed from 35 kg bags into the input bin at ground level. A vacuum feeding system transports the tea to a hopper, from where it is released onto a series of magnetic drum separators. As the tea passes over the drums, iron particles adhere to the drum surface due to the powerful internal magnets. The iron is then separated and collected in designated trays, while the cleaned tea proceeds for further processing.

This system is not suitable for materials with high viscosity or large particle sizes by volume or weight.

Schematic Diagram of Working System of IFR

Advantages of the Iron Removal System (IFR)

- Comprehensive system ensuring efficient iron separation down to 30 ppm.

- Equipped with PLC controls for flexible flow rates and enhanced safety features.

- Production capacity can be scaled from 3.5 to 4.5 tons per hour.

- The three-drum separator design, combined with a magnetic grill, offers superior iron removal performance from input levels of 400 ppm to output levels as low as 30 ppm.

Videos of IFR

FAQ for Magnetic Iron Filing Removal Machine

- 1) How much maximum magnetic power can be get?

- Ans - 4500 Gauss. Which is sufficeint to remove the fine size iron contamination.

- 2) How to clean iron particles from drum?

- Ans - Drum separator is a self cleaning system. It separates iron & non iron material through two different outlets.

- 3) Where to install it?

- Ans - Below material feeding system like screw conveyor, bucket elivator, conveyor belt, vibro feeder etc.

- 4) Does it require power supply?

- Ans - Yes, Magnetic drum rotates with the help of the induction motor. PLC & VFD can configured witht the system.

- 5) What is the drum rpm rate?

- Ans - 20 rpm.

- 6) What is the efficiency of the IFR machine?

- Ans - The m/c with three drum separators placed one above the other and the magnetic grill is capable of giving the output ppm as low as 30 ppm from an input ppm of 400. The production rate can be scaled up from 3.5 tons /hr to 4.5 tones/hr.

- 7) IS this IFR machine is advisable to tea processing industry only?

- Ans - Though IFR machine is specially made for Tea processing industry, Every industry is shoule this kind of drum separator to achieve the desired IRON PPM level into final output product.

- 8) What will be the life for magnet?

- Ans - It is a permanent magnet it will not loose its magnetism. Magnet can get demagnetized in two cases, a) When it get damaged. b) When magnet get exposed beyond specified operating temperature. But magnet can loose its magnetism 2% to 3% over the span of 5years.

- 9) Can we recharge the magnet?

- Ans - No. Magnet cannot be recharged.

- 10) How we can measure the power of magnet ?

- Ans - Magnetic intensity can be checked by gauss meter. We also provide calibration services, which we will be valid for 1year

- 11) What is the M.O.C for the Housing, Hopper & Structure.

- Ans - M.O.C for the drum, housing, hopper is stainless steel only, Structure of the drum separator is made up of MS.

- 12) What is the area require to install this kind of machine?

- Ans - The machine occupies a floor space of 15 sq meters approx and has a height of 5.5 meters. It consists of Input Bin, Base Frame Assembly, Vacuum Feeding System, Tea Feeding Hopper, Drum Separators Along With Geared Motor Drives, Control Panel and Associated Electric Wiring.

- 13) Can we feed material manually?

- Ans - Yes but it is always recommended to use feeding system for regulated & even material feeding. This will help for better iron removal from material.