Product Description:

Separating fine iron impurities is always a headache for a food as well as other material processing industries. It requires high power magnetic systems & cleaning these systems is also a time consuming process which makes it difficult where the process line can not be stopped frequently.

The Roller magnetic separator is the ideal solution for such application. The magnetic roller develops 10000 Gauss value on its magnetic poles which enable it to trap & separate even very fine & feeble magnetic impurities.

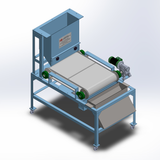

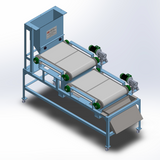

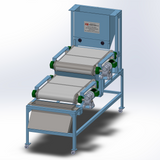

The self cleaning feature makes it preferable to use in continuous production processing lines. Roll separator available in one, two & three stages depending on the product type, flow rate & magnetic impurity percentage in the product.

Construction:

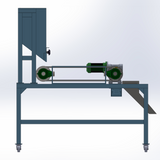

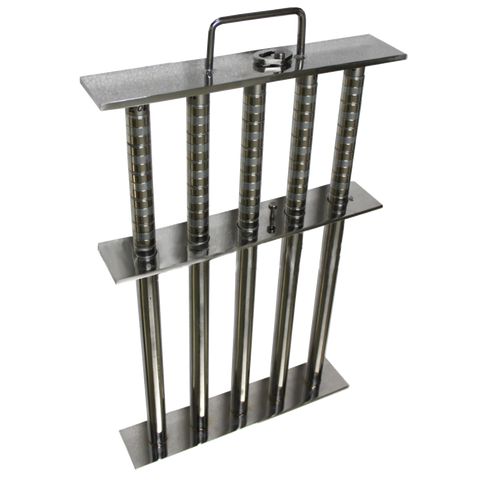

Roller separator assembly consists of a Head magnetic roller, Tail non magnetic roller, motor, Belt, Feeder, Material collecting chutes & body structure.

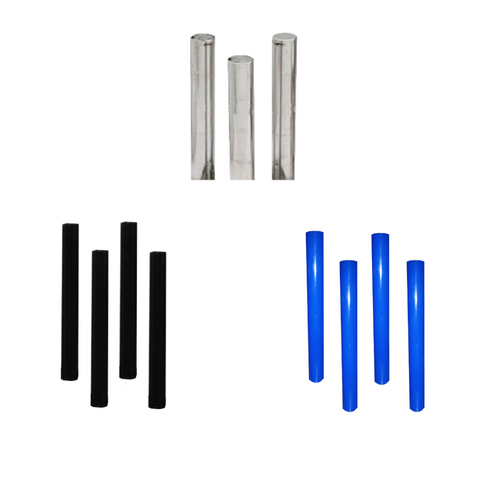

The magnetic roller is made by using strong NdFeB magnets.

The magnetic & non magnetic rollers are connected by a conveyor belt on which the material is fed through the feeder.

The belt material is generally a Kevlar but depending on the material characteristics it can vary.

The feeder & other parts which come in contact with material are made up of S.S. & the structure is made up of M.S.

The chutes are provided below the magnetic roller to collect magnetic impurities & impure product separately.

Working:

The material is being fed on the revolving belt through feeder. At the discharge end when the material comes into contact with the magnetic influenced area then the roller catches the magnetic particles & it gets carried along with the belt to the down side.

When the magnetic particles move away from the magnetic influenced area, it gets dropped from the belt into the chute located at the down side.

The purified material passes in forward direction & falls into the collecting chute.

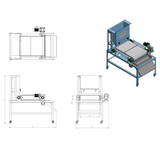

The below sketch shows the working principle of Roller magnetic separator very well.

| High Intensity Single stage Roll type Magnetic Separator: NdFeB (Rare Earth) Magnets, Peak flux density value on belt 10,000 ±1000 Gauss |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Belt width |

Roller Diameter ‘A’(mm) |

Roller Length ‘B’(mm) |

Total Length ‘C’(mm) |

Total Width ‘D’(mm) |

Total Height ‘E’(mm) |

Power (Kw) |

Feed Capacity (t/h) |

| HSRS 1 | 225 | 100 | 250 | 1225 | 566 | 1160 | 0.37 | 0.3 - 0.5 |

| HSRS 2 | 475 | 100 | 500 | 1225 | 816 | 1160 | 0.37 | 0.75 - 1 |

| HSRS 3 | 725 | 100 | 750 | 1225 | 1066 | 1160 | 0.37 | 1.5 - 2 |

| HSRS 4 | 975 | 100 | 1000 | 1225 | 1316 | 1160 | 0.55 | 2.5 - 3 |

| HSRS 5 | 1225 | 100 | 1250 | 1225 | 1566 | 1160 | 0.55 | 3.5 - 4 |

| HSRS 6 | 1475 | 100 | 1500 | 1225 | 1816 | 1160 | 0.55 | 4.5 - 5 |

| High Intensity Double stage Roll type Magnetic Separator: NdFeB (Rare Earth) Magnets, Peak flux density value on belt 10,000±1000 Gauss |

||||||||

|---|---|---|---|---|---|---|---|---|

| Model | Belt width |

Roller Diameter ‘A’(mm) |

Roller Length ‘B’(mm) |

Total Length ‘C’(mm) |

Total Width ‘D’(mm) |

Total Height ‘E’(mm) |

Power (Kw) |

Feed Capacity (t/h) |

| HDRS 1 | 225 | 100 | 250 | 1865 | 566 | 1360 | 0.37 | 0.3 - 0.5 |

| HDRS 2 | 475 | 100 | 500 | 1865 | 816 | 1360 | 0.37 | 0.75 - 1 |

| HDRS 3 | 725 | 100 | 750 | 1865 | 1066 | 1360 | 0.37 | 1.5 - 2 |

| HDRS 4 | 975 | 100 | 1000 | 1865 | 1316 | 1360 | 0.55 | 2.5 - 3 |

| HDRS 5 | 1225 | 100 | 1250 | 1865 | 1566 | 1360 | 0.55 | 3.5 - 4 |

| HDRS 6 | 1475 | 100 | 1500 | 1865 | 1816 | 1360 | 0.55 | 4.5 - 5 |

Usage:

The magnetic roll separator is used to remove mainly fine iron contamination which is harmful for the further processing e.g. Glass sand, Mineral industry, Food products, Quartz industry etc.

It is also Known a Magnetic Destoner as it can remove small stones, soil particles which are present in grains.

Features:

- High magnetic power i.e. 10000 Gauss on its magnetic poles.

- Available in 2 & 3 stages also.

- High efficiency.

- Self cleaning process.

- Low maintenance cost.