Product Description

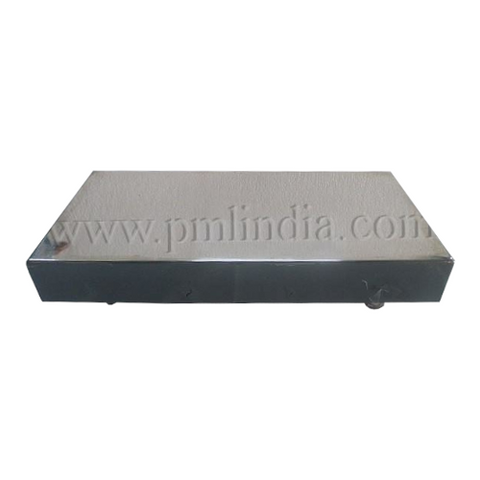

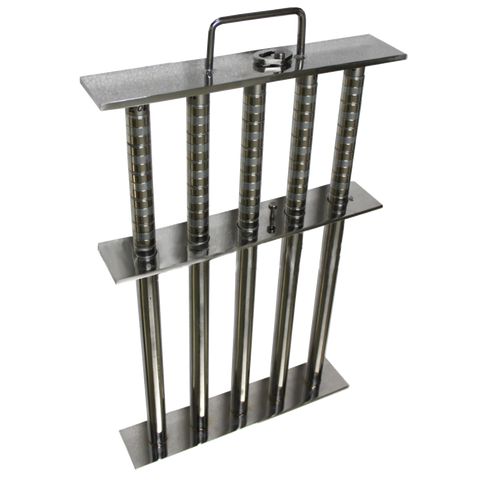

The Pneumatic Chute Magnet is used for the separation of iron particles from dry, granular or free-flowing products/materials in pneumatically conveyed lines up to 1 Bar. The Pneumatic Chute Magnet is made by using stainless steel with magnetic rods.

The Pneumatic Chute Magnet is efficiently utilized if contamination is within 1% to 1.5% by weight. For higher levels of contamination more magnetic elements should be used.

Applications

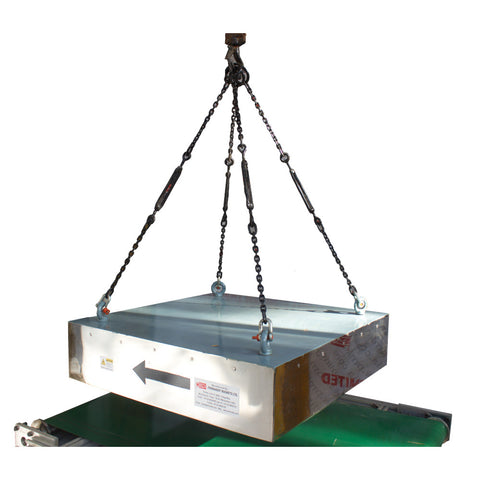

This high intensity magnetic separator is mainly designed to be installed into pneumatic conveying lines with air flow up to 25 m/s. The Pneumatic Chute Magnet system will be of great interest to the food and pharmaceutical industries with products like flour, sugar, starch, pharmaceutical drugs and other powders and granules. The special housing design allows the product to pass through the unit in both directions. The Pneumatic Chute Magnet can be supplied with various flanges to suit the customer’s requirements.

Industries using Pneumatic Chute Magnet:

- Plastic industry

- Food industry

- Chemical industry

- Pharmaceutical industry

Pneumatic Chute Magnet have following features:

- Welded stainless steel construction

- Food Grade Finish and Gasket Standard

- Tool Free Guard Removal

- No Line Pressure Drop

- Leak-Resistant Silicone seal up to 2 BAR

- Vertical or Horizontal Installations

General Specification of Pneumatic Chute Magnet:

Standard sizes of Pneumatic Chute Magnet

| Pneumatic Chute Magnet | |||||||

|---|---|---|---|---|---|---|---|

| Model No. | A(mm) | B(mm) | C(mm) | H(mm) | No. of Rods | Magnetic Gauss | Pressure |

| P001 | 75 | 180 | 180 | 460 | 4 | 12000 | 1 bar |

| P002 | 100 | 180 | 180 | 460 | 4 | 12000 | 1 bar |

| P003 | 125 | 240 | 220 | 500 | 6 | 12000 | 1 bar |

Construction of Pneumatic Chute Magnet:

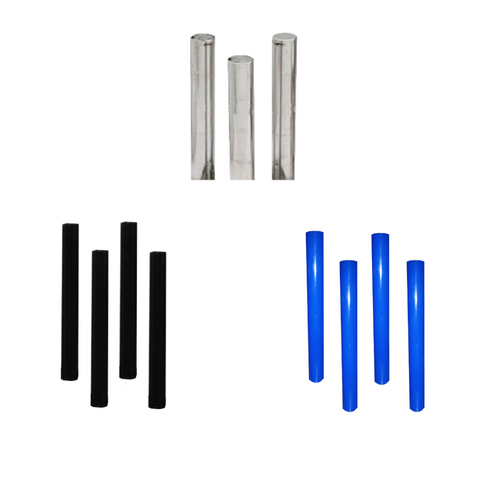

The Pneumatic Chute Magnet is made up of magnetic elements, which are fitted in a housing. Magnetic Elements are made up of high-intensity rare earth magnets ( NdFeB ). All the components are made up of Stainless Steel 304/316 material. The overall construction of The Pneumatic Chute Magnet can also be made as per the customer specification and sizes.

Customized Pneumatic Chute Magnet

In case you are interested in purchasing a custom designed Pneumatic Chute Magnet, please do let us know the details below.

- Pressure

- Flow rate

- Material size

- Inlet & Outlet sizes

- % of Iron particles in Input Material

Why PML Pneumatic Chute Magnet ?

- 60 years of experience in design and development of Permanent Magnets and Magnetic Separator

- Easy to clean and no maintenance cost and preventing expensive shutdown and delays for equipment down the process line

- No power cost

- Installation of these Pneumatic Chute Magnet improves product quality thereby enhances product value

- Services such as magnetic calibration/Audit are available

- PML also makes customized design of the Pneumatic Chute Magnet