FAQ for Shielding

Q.1. What is a magnetic shield and how do magnetic shields work?

- Ans: Magnetic shielding materials re-direct a magnetic field so it lessens the field's influence on the item being shielded. Shielding does not eliminate or destroy magnetic fields, nothing does. It does, however, provide an easy path for the magnetic field to complete its path. You may think of it as a magnetic field conductor. This leads to what type of material can provide the best path for magnetic fields and thus create shielding. Since the field is attracted to the shielding material it stands to reason that if a magnet is attracted to the material (ferromagnetic material), that material can provide some amount of magnetic shielding.

Q.2. Which are the parameters needed to consider for designing a magnetic shield/Flux concentrator?

- Ans: In designing, fabricating, and testing shields, the following parameters are essential to developing the best “strategy” for shield design and for predicting how the magnetic shield will perform in attenuating magnetic fields.

- -Geometry

- -Shape

- -Size

- -Magnetic field continuity

- -Closer

- -Length to Diameter Ratios and the Impact of Openings

Q.3. What is annealing and how does it affect shielding magnetic materials?

- Ans: In metallurgy and materials science, annealing is a heat treatment that alters the physical, magnetic and sometimes chemical properties of a material to increase its ductility and reduce its hardness/stres, making it more workable. CO-NETIC and NETIC magnetic shielding alloys have a positive coefficient of permeability with respect to temperature. This is a quick way of saying that the permeability increases as temperature increases. This occurs until operating temperature nears the Curie temperature, defined as the temperature where permeability goes to 1 and the alloy becomes magnetically transparent. Note: Temporary temperature excursions above curie temperature do not degrade the alloys. Shielding function is restored when the temperature again falls below Curie point.

Q.4. How to decide the geometry of a shield?

- Ans: Shields such as cylinders or boxes with rounded corners are beneficial because it is difficult for magnetic flux lines to turn 90 degrees. Gentle radii provide a better path for magnetic flux lines than sharp corners. Some percentage of magnetic flux lines that are already entrapped within the skin depth of a material will tend to leave the material whenever they encounter a sharp corner. To contain and redirect flux that is already entrapped, designs should generally include gentle radii. When designing your shield, it is a good idea to keep the shape simple, always envisioning a “path of least resistance” upon which the magnetic flux can travel. Shield size is a significant factor in its overall performance. All things being equal, smaller shields result in better performance, which means that it should always be your goal to design a shield that will envelop the component or space you are attempting to shield as closely as possible. Additionally, because materials are a major cost component in shield design, smaller shields will yield better performance at a lower cost.

Q.5. How to decide materials of magnetic shield for particular application?

- Ans: Magnetic shielding materials are selected based on their specific characteristics, usually with respect to permeability and saturation. Permeability determines the effectiveness with which a given shield can entrap magnetic flux by offering it a low reluctance path. Saturation determines the maximum flux density that a given shield can entrap based on its thickness and the intensity of the magnetic field. It is important to remember that permeability and saturation are inversely related. As permeability values increase, saturation levels decrease. This means that the highest permeability alloys such as A mumetal have the lowest saturation values. Because a saturated shield is a poor attenuator, it is important to select materials with adequate saturation characteristics to withstand the strength of a given source field while still providing the required attenuation of that field. Most magnetic shields made are constructed from high permeability materials such as A mumetal, an 80% Nickel-Iron alloy designed especially for magnetic shielding applications.

Q.6. What Is The Difference Between RF and Magnetic Shielding?

- Ans: Radio frequency (or RF) shielding is required when it is necessary to block high frequency - 100 kilohertz and above - interference fields. These shields typically use copper, aluminum, galvanized steel, or conductive rubber, plastic or paints. These materials work at high frequencies by means of their high conductivity, and little or no magnetic permeability. Magnetic shields use their high permeability to attract magnetic fields and divert the magnetic energy through themselves. With proper construction, magnetic shielding alloys have the ability to function as broadband shields, shielding both rf and magnetic interference fields.

Q.7. How to decide the minimum air gap for a magnetic shield/flux concentrator?

- Ans: The minimum air gap for magnetic shield depends upon the dimensions of bus bar,sensitivity of the current sensor.

Q.8. How does the number of layers affect magnetic shielding?

- Ans: Multiple layer shields are usually larger and are used frequently in a research environment where it is not only necessary to shield out the earth’s magnetic field, but in some cases, to create a new magnetic field inside the shield which has known characteristics regarding stability and field strength over given moments in time.It is also used to improve the attenuation of the shield when it subjected to a very high magnitude of the magnetic field.

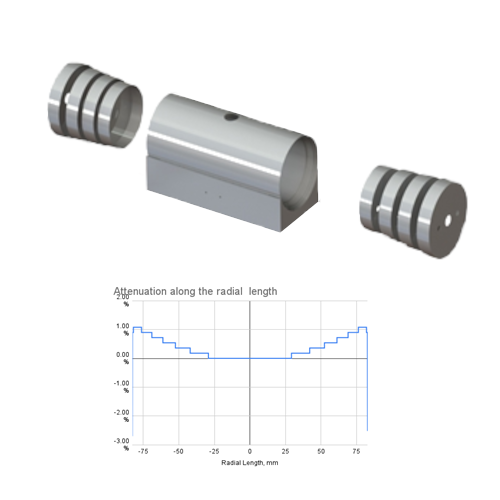

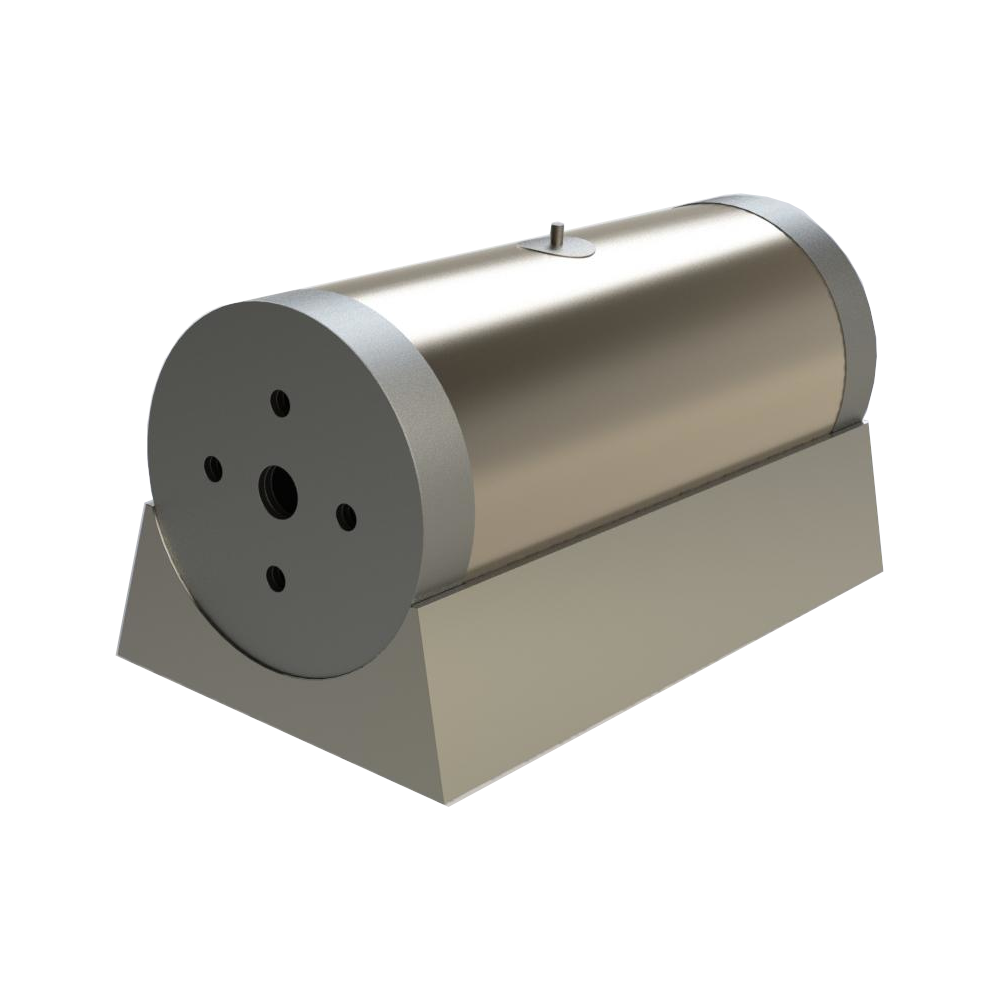

Q.9. What is flux concentrator and what is the working mechanism?

- Ans: Flux concentrators intensify the magnetic field in certain areas and can assist in increasing efficiency in power or heat transfer. Without a concentrator, the magnetic field is more likely to spread around and intersect with any electrically conductive surroundings.